A Few Considerations To Make When Measuring

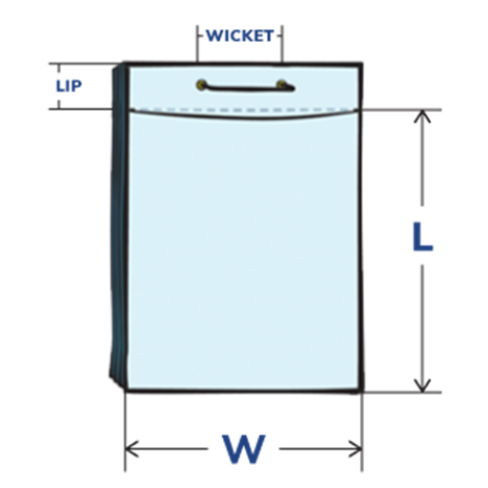

Poly Bags

A Few Considerations To Make When Measuring

Poly Bags

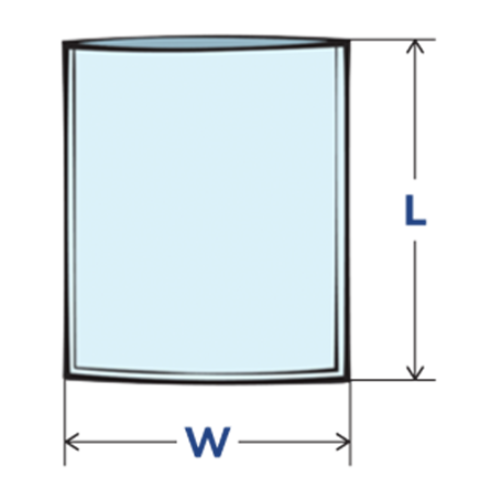

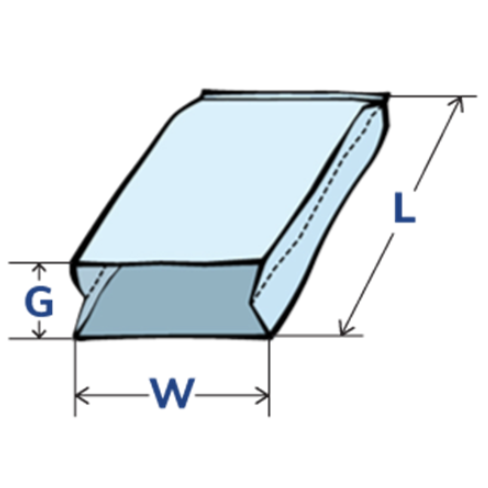

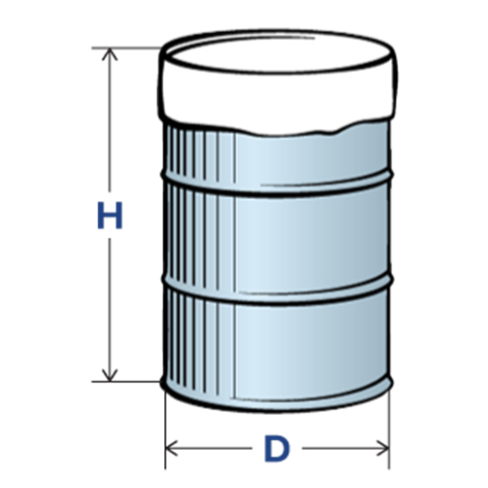

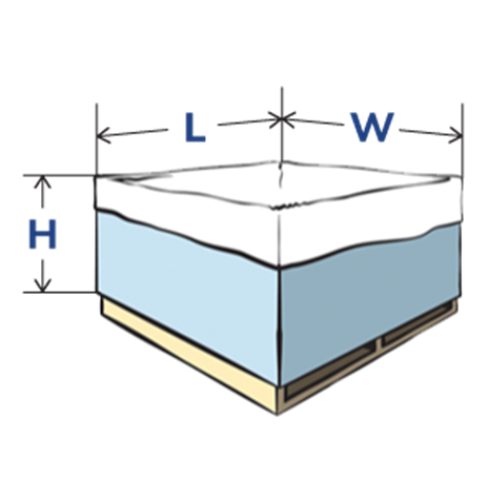

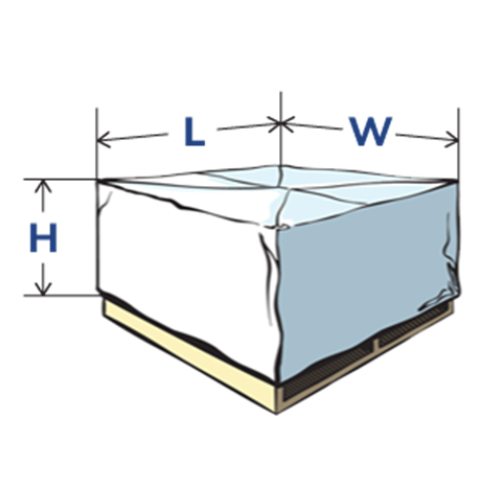

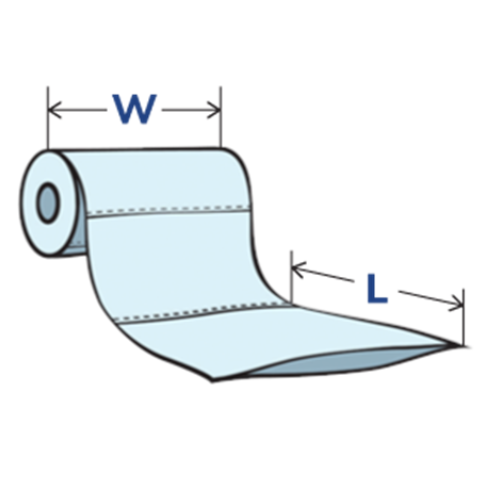

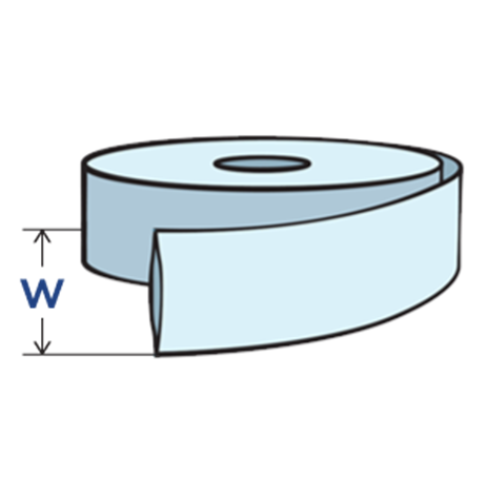

Measure your product first : Before you consider what size poly bags you’ll need, it’s important to have a complete measurement of your product. This will help you choose the appropriate size poly bag for your order.

Consider the poly bag’s opening size : Always be sure to check that the poly bag’s opening size will be wide enough to accommodate your product’s unique dimensions.

Not sure where to start? Ask the experts! Always be sure to check that the poly bag’s opening size will be wide enough to accommodate your product’s unique dimensions.

Not sure where to start? We're here to help!

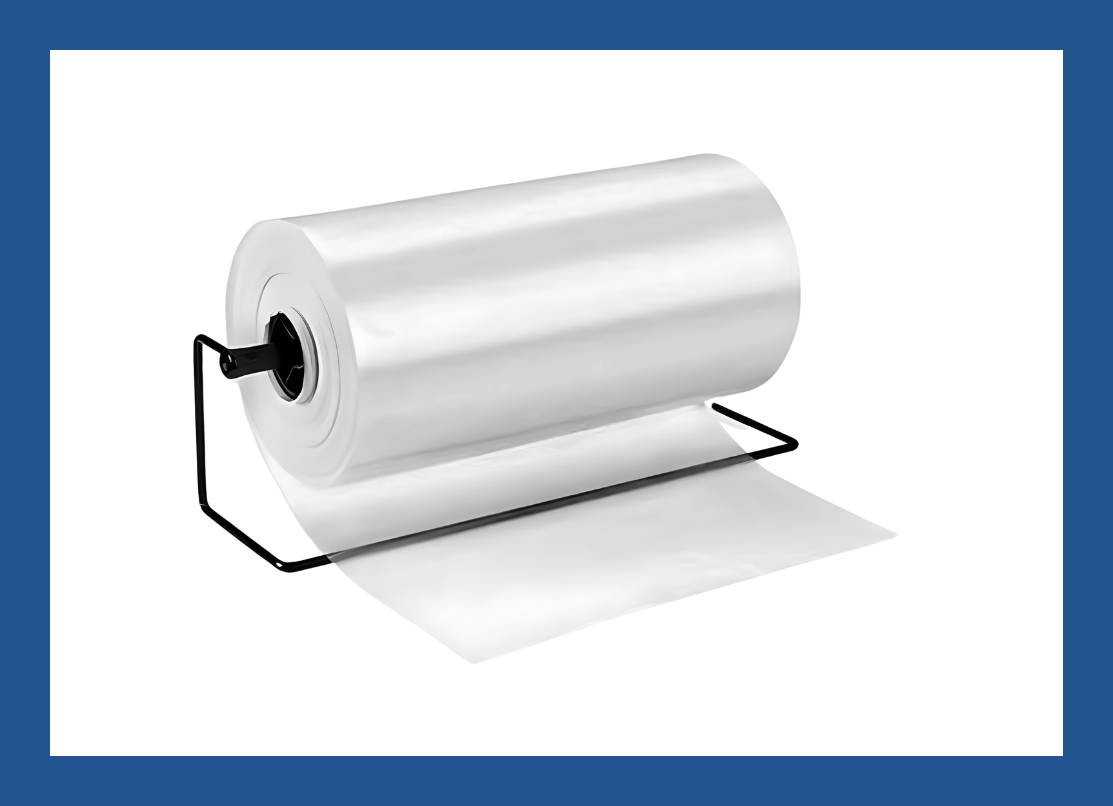

There's a lot to consider when it comes to ordering poly bags, plastic liners, or rolls of film. The MAA Packaging team is here for you. Let us know what you're looking for, and we'll help you determine which poly bag and plastic product options are best for your application.