At MAAPackaging, we hold Health and Care at the pinnacle, where packaging forms the basis of protecting and delivering healthcare with highest safety standards. We will listen, suggest, develop and deliver Pharma Packaging Solutions across geographies for all dosage forms of highest quality standards and be a preferred supplier of Innovative Packaging Products.

MAA Packaging offers high-barrier non-toxic, multi-layered laminates with variety of applications for the Pharmaceutical Industry. These laminates are suitable for sachets, unit dose FFS application, contraceptive packaging and for packaging of bulk drugs. The laminates are available with various surface as well as reverse printing options along with overt anti-counterfeit features. Various thickness configured as per customers requirement.

MAA Packaging offers Child-Resistant Senior-Friendly (CRSF) healthcare packaging offers peel-push, peelable, and push-through variants for pharma applications to avoid accidental misuse by children and enable convenience in usage for senior citizens. The CRSF product-range covers all the DMF-registered formats. All variants available in printed options. Configuration of Paper and Foil Tailormade.

MAA Packaging Hard-Tempered Blister Lidding Foils combine innovative printing solutions on Roto Gravure and Flexo. Various print patterns and micro-text printing are made available in 8-color, 6-color, 4-color, and 2-color with solvent based inks and water-based inks.The printing is further enhanced by adding anti-counterfeit features such as UV inks, thermochromic inks, and color-shifting inks. Options are also made available in reverse printing with precision in registration.

Cold form Alu Alu is a first-rate multilayered structure suited for highly sensitive formulations in the most aesthetically-pleasing format that provides with protection against water vapor and gases and also acts as an excellent barrier against light and dust.The Cold Form Alu blisters are available with various printed patterns to give unique brand identity and also act as anti-counterfeit feature for the Pharma products.

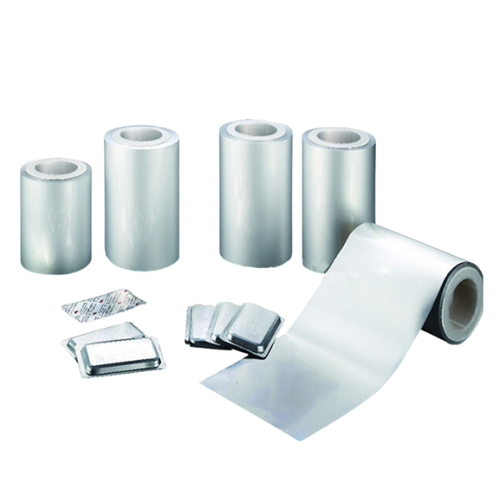

Strip Foils offer a cost-effective packaging option for highly sensitive pharmaceutical products. An ideal packaging technique for protection and supply of pharmaceuticals, strip foils offer a secure and more user-friendly alternative compared to bottled capsules and tablets. Our range of Strip Foils (30µ/40µ Alu Foils with extruded Polyethylene 38µ) depend on your demands for better barriers and longer shelf lives of tablets and capsules. Strip Foils pack your formulations in exact dimensions that make the pharmaceuticals appear organized, separated, and secure.

Realising the need for Laminate Structures to pack powders, liquids, gels etc. We have a State-of-the-art Tandem Extruder with Auto Dies for precision. The machine offers a web width up-to 1800 mm. We offers up-to 4 layers of Co- extruded polymers catering to Pharma, Food and Healthcare segments. The laminates are made available in printed and unprinted form.

Packaging films & foils are used for providing protection to the products being packed in it. The protection is supposed to be provided from physical factors such dust, shocks etc as well as environmental factors such as moisture, gases & light. Tropical foil is one such packaging. A tropical foil is composed of soft Alu foil laminated with OPA on dull side and coated with heat seal lacquer on bright side. The heat seal lacquer can be compatible for sealing with only PVC or both PVC & PVdC. Tropical foils can be considered as a secondary packaging for the tablet or capsule. The pharmaceutical product (tablet or capsule) is first packed in a polymer (PVC or PVdC) and Alu lidding foil packaging system. The HSL coated side of Tropical foil is then sealed with the outer polymer layer in blister packaging system to provide additional protection. Tropical foils derive its name for the target climatic conditions, i.e. tropical conditions where high moisture or humidity is observed. Tropical foils are designed to provide protection to pharmaceutical products in such tropical conditions.